Hello:

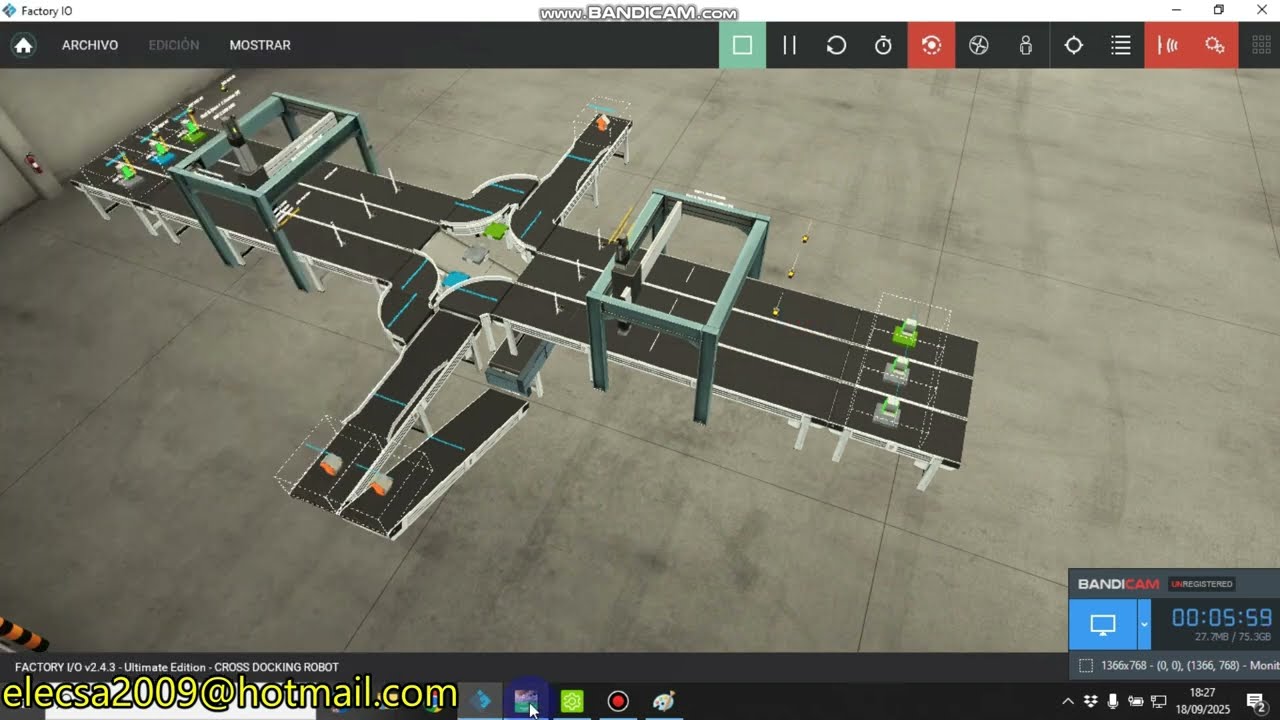

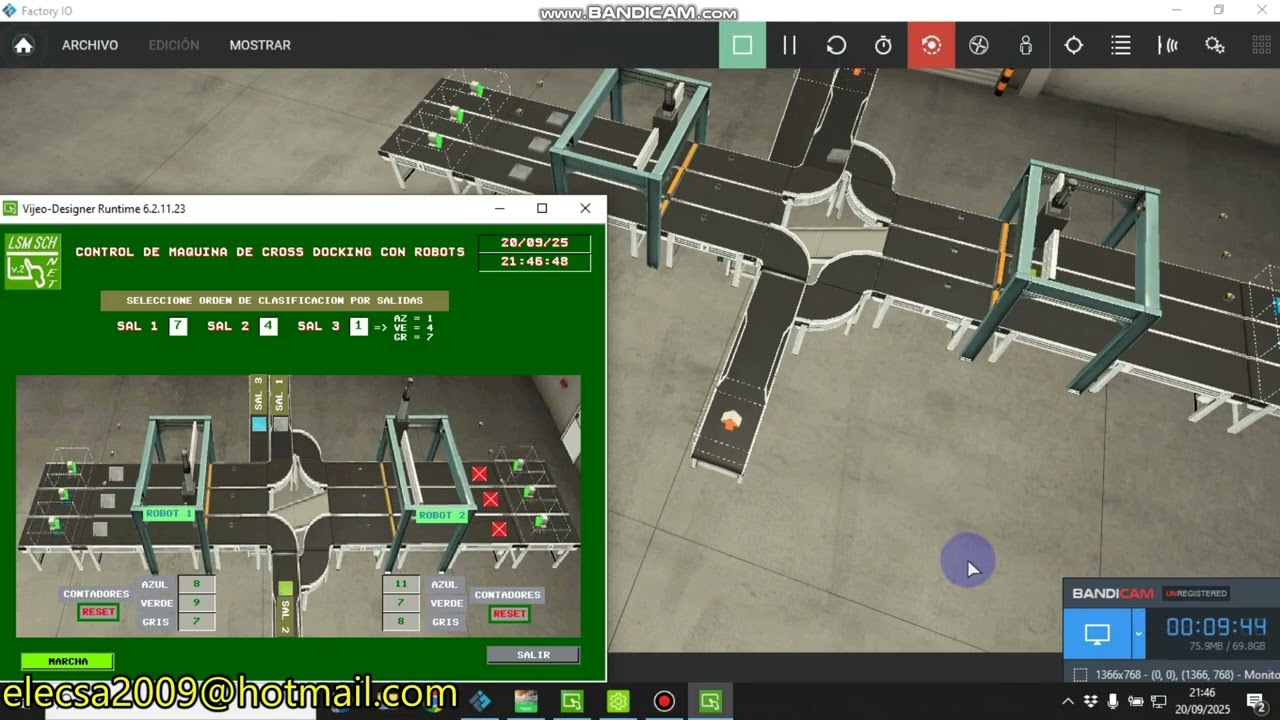

Creating a scene is more laborious than programming it. I suppose the communications between FACTORY IO and the PLC, plus the recorder, plus everything that happens on the PC affects the simulation. However, if instead of simulating from the server, we do it from a physical PLC, the communication is much better and faster. Still, you can’t ask for more. Keep in mind that the tape is ON when the robot picks up the part; it’s not the same as if it bumps into an object.

We continue with this project. Although two unforeseen issues have been resolved during “machine startup,” which we could say is that FACTORY IO allows us to perform startups, more unforeseen issues will surely arise, but hey, we’ll enjoy them, learning something new every day.

I hope students and teachers will take on this project, which is unparalleled anywhere in the world.

Greetings